Easy Way How to Test Capacitors

Hay! Hope you are doing great.

A circuit board usually has resistors, capacitors, inductors, ICs, connectors, and a few other components. It is common, for these components to get burned and need replacement.

The components that have higher chances of burning out are resistors, capacitors, and rarely the ICs. The reason is, that most resistors and capacitors are at the front end of any board. And sometimes over-voltage burns them out.

When it comes to resistor and IC, you can identify the bad one by just looking at it on the board. A burnt IC or resistor is busted open, and you can find it in seconds on the board.

However, this is not the case for the capacitor.

Funny Shirt for Electronics People.

No What's Up, it is WATTS (unit of power) UP 😛

In the case of a capacitor, things are a little different. If you are lucky, you will find the bad capacitor just by looking at its top, it will be busted open.

But what if you are not that lucky?

The real problem you would face, a normal-looking capacitor can be a bad one. So you have to desolder all the capacitors from the board, test each one, find the bad guy, and resolder each and every one back on the board. Which is not a good way and no one wants to do it.

Don't worry.

In this post, we will definitely discover a way how to test capacitor without desoldering it from the broad.

Hopefully, you will enjoy and benefit from this article.

Why multimeter is not a good choice for testing bad capacitors?

Sure! You have a capacitance meter or multimeter with a capacitance feature and by using it you can verify the capacitance value of a capacitor. And sometimes you can use the same meter to identify a bad cap if the capacitance value is not in the tolerance range of the manufacture provided data.

i.e. If the capacitance value is dropped 10% below the provided tolerance value, then your capacitor needs to be changed right away. (Example: Cap is rated for 470uf with 10% tolerance. A Bad cap would have a value less than 380uf on a capacitance meter)

But, let's just face it.

You just cannot test a bad capacitor inside or outside a circuit board by measuring its capacitance value with a capacitor meter or a multimeter. Because in such a situation mentioned devices lead you into false reading, and you may not be able to actually tell if the capacitor you tested was actually a bad or right one.

Why?

- The reason is, that when a capacitor is inside the circuit board, there are a lot of other components in series or parallel with it. So you get the equivalent reading, not the actual one.

- When the capacitor is outside the board, sometimes a bad capacitor may give you a proper capacitance value on the multimeter or capacitor meter.

Solution: Test a capacitor without desoldering it by using an ESR meter

No doubt, multimeter or capacitor meters are used to measure capacitance. They just cannot be trusted to tell you if the capacitor is bad or good, whether it is outside or inside the circuit board.

So, how can I test a bad in-circuit capacitor?

There left one choice we can use to test a capacitor, and that is by measuring its equivalent series resistance (ESR). You know, when the capacitor is in use for a long time. Its capacitance value tends to decrease because the capacitor dries out with time, but its internal resistance value increases.

By measuring this internal resistance of capacitors we can easily identify bad capacitor whether it is in-circuit or off the circuit. And to help us measure ESR accurately, we can use any market available ESR meter.

In summary, the best solution to test a capacitor without desoldering it actually for the circuit board is either using an ESR meter or smart tweezers. Both work the same and are fine to use. But the ESR meter is preferred for through-hole capacitors, and the latter one is preferred to test SMD capacitors.

In the rest of the article, I give more info on what are the mentioned devices, and how they test in-circuit capacitors.

What is an ESR meter?

The term ESR stands for equivalent series resistance, measured in Ohms, meaning the ESR meter is a device used to determine the equivalent series resistance of a real capacitor without desoldering it from a circuit.

This device cannot measure the capacitance, and can only be used to test a capacitor.

An ideal capacitor has an ESR value equal to zero, but in reality, it is very very less; close to the ideal value. A high ESR value is the first indicator of a capacitor's failure.

The increase in the ESR value increases both voltage drops within the capacitor and the heat. The heat produces in the capacitors is due to resistive heating, and this heat causes the capacitor to leak out.

If you do not test the electrolytic capacitor for ESR value with an ESR meter, you may not be able to tell if the capacitor is a good or bad one.

Testing in-circuit bad capacitors using an ESR meter

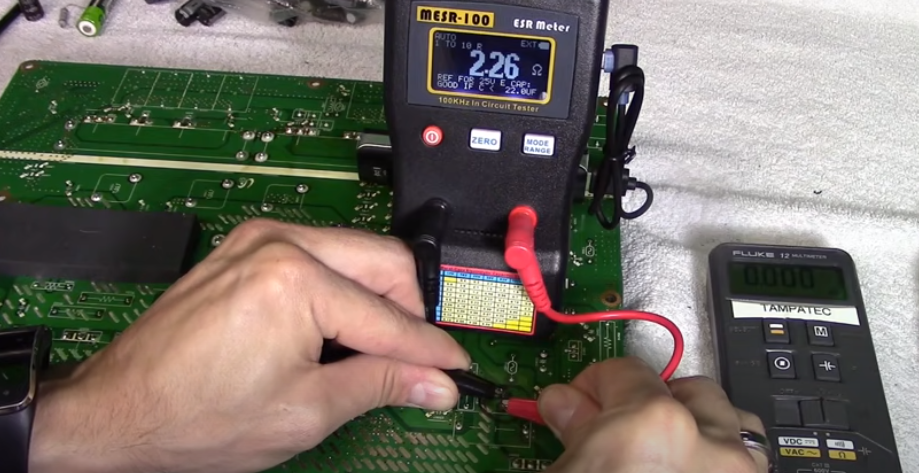

The following are the quick steps to test any in-circuit capacitor with an ESR meter.

- Discharge the under-test capacitor first. This is so important and crucial, if you accidentally forget this step, you may end up destroying your ESR meter. For extra knowledge, always discharge a capacitor before measuring any parameter of it.

- Discharging of a capacitor can be done by shorting its legs by any available means. But don't just short the legs together with low resistance wire, a good practice is to use a high resistance material.

- Turn on the ESR meter, and short its leads until you get 0 reading on its screen. If the screen is already showing 0 reading, then there is no need to short the leads.

- Place the red lead of the ESR meter to a positive and black lead to the negative terminal of the capacitor under test.

- Note the readings on the ESR meter.

- Compare the reading with the table given on the body of the ESR meter. If the ESR value is in the given range the capacitor is good and needs no changes, if not then it is a bad one and needs replacement.

- If the body of ESR is not giving any table, use the datasheet of the capacitor to read its ESR value.

The datasheet of every capacitor has listed its ESR value at the frequency of 100kHz and specific voltage rating. Deviation from this value helps us to decide whether the capacitor needs to be changed or not. Usually, the ESR of a bad capacitor increases.

Furthermore, a good capacitor would measure almost like a short circuit, and all other parts connected in parallel with it will have minimal influence on the end measurement. This is the feature that makes an ESR meter an irreplaceable tool for troubleshooting electronic equipment.

So, if you really want to find out and fix the bad capacitors in your devices, you require a decent ESR meter. You can find good ESR anywhere.

Just search for it.

I recommend and like this ESR meter, the MESR-100 V2 (Product link). It is less expensive and is specifically designed for in-circuit capacitor testing and in-circuit ESR measurements. You can also buy the same meter from Amazon as well, MESR-100 (Amazon link).

You can also check out this ESR measuring meter (Amazon link).Basically, this is a combined LCR meter with high accuracy. The only problem I see in this meter is the price range. It is a little expensive for me.

Smart Tweezers

Usually, an ESR meter can do all the job for you, but when it comes to SMD components it doesn't come as handy as a smart tweezer. If you decide to go with ESR, you will be fine, but the smart tweezer (Amazon link) is fun and a wonderful tool to have in your lab, in my opinion.

The real concern with smart tweezers is, that they are expensive. The last time I checked, its price was around $140. But besides using it just to test capacitors, it can be your awesome portable LCR meter too.

All the measuring steps are the same as I discussed above for the ESR meter.

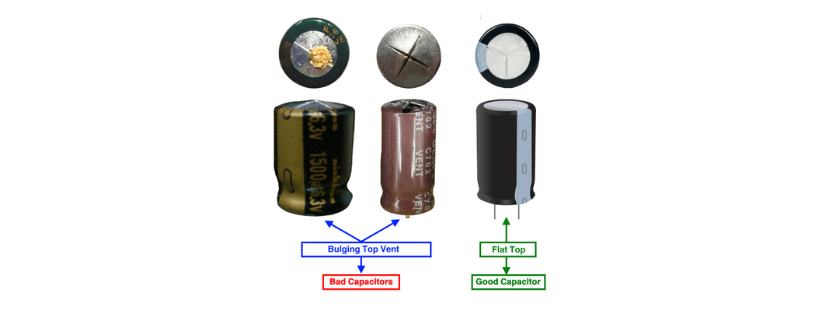

Visually seeing a bad capacitor

Instead of using an ESR meter or tweezers, we can also test a capacitor without desoldering it by general inspection.

A bad electrolytic capacitor gets swallowed at the top side, you see such one in the circuit; just replace it without wasting your time testing it.

The capacitance value may be in the good value range when you test it off the circuit with a multimeter or capacitor meter, but still, it is a bad one.

Conclusion

You just cannot test a bad capacitor both inside or outside a circuit board by capacitance meter or multimeter. The reason is. they both may lead you to false results.

The only solution to test capacitors without desoldering is by measuring their equivalent series resistance (ESR). This value is measured by an ESR meter.

An ESR meter sends a 100kHz frequency alternating current into the capacitor under test. The current produces a voltage across the capacitor and then using some mathematics the ESR is calculated and displayed on the screen.

You get a drifted ESR value after comparing it with an ESR chart, you have a bad capacitor.

And well, there you have it. Now, if a reader like me, read the conclusion first. You read it. It's time to go to the beginning. But you are the reader, making this far. I hope you enjoyed it.

Thank you and have a good time.

Other useful posts

- 11 Best cheap ESR meter (For Easy Bad Caps Testing 2022)

- Learn Electronics for Beginners – An Easy Step by Step Guide

- Reviewing Excelvan M6013 Meter [The Best Capacitance Meter]

Source: https://www.yamanelectronics.com/test-capacitor-without-desoldering/

0 Response to "Easy Way How to Test Capacitors"

Post a Comment